In today’s fast-paced world, where convenience is key and efficiency is paramount, the role of packaging machines in various industries, particularly the food industry, cannot be overstated. Among the myriad packaging solutions available, automatic pouch packaging machines stand out for their versatility, speed, and precision. In this blog post, we’ll delve into the importance of packaging machines in industries, explore the functionalities of pouch packing machines, discuss the different types available, and touch upon their costs.

Streamlining Efficiency in the Food Industry: The Role of Automatic Pouch Packaging Machines

Importance of Packaging Machines in Industries

Packaging machines play a pivotal role in industries, especially in the food sector, by providing efficient and standardized packaging solutions. They ensure product safety, extend shelf life, maintain product quality, and enhance the overall appeal of the packaged goods. Moreover, packaging machines streamline production processes, reduce labor costs, minimize product waste, and enhance operational efficiency, thereby driving profitability and competitiveness in the market

Understanding Pouch Packing Machines

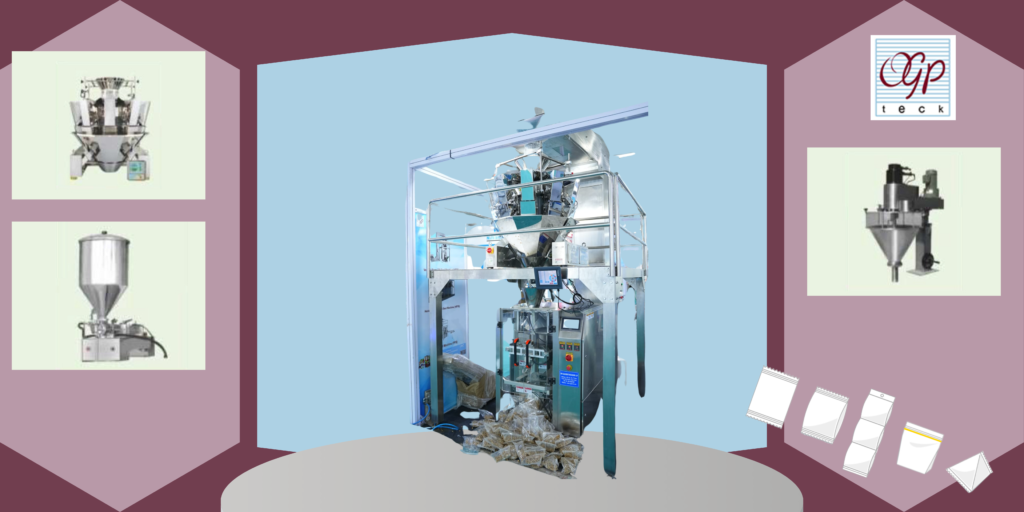

A pouch packing machine is a type of packaging equipment designed to automatically fill and seal pouches with various products such as liquids, powders, granules, or solids. These machines are equipped with advanced mechanisms that facilitate precise filling, sealing, and packaging of the contents into pouches of different shapes and sizes. Pouch packing machines are widely used across industries due to their versatility, reliability, and cost-effectiveness.

Operation of Pouch Packing Machines

Operating a pouch packing machine typically involves a few simple steps:

Setup: Adjust the machine settings according to the requirements of the product to be packaged, such as filling volume, sealing temperature, and pouch dimensions.

Loading: Place the empty pouches or rolls of packaging material into the machine’s feeding mechanism

Filling: The product is dispensed into the pouches either manually or automatically, depending on the machine’s configuration.

Sealing: The filled pouches are sealed using heat, pressure, or ultrasonic technology to ensure airtight packaging.

Quality Check: Inspect the sealed pouches for any defects or irregularities before they are discharged from the machine.

Types of Pouch Packaging Machines

Pouch packaging machines come in various types to cater to different packaging requirements.

- Vertical Form Fill Seal (VFFS) Machines: These machines form pouches from a roll of packaging material, fill them with the product, and seal them vertically.

- Horizontal Form Fill Seal (HFFS) Machines: HFFS machines form, fill, and seal pouches in a horizontal direction, making them ideal for packaging larger or bulkier products.

Automatic Multi-Channel Packaging Machines

An automatic multi-channel packaging machine is a sophisticated variant that can handle multiple pouches simultaneously, significantly increasing production output and efficiency. These machines are equipped with multiple filling and sealing channels, allowing them to process several pouches simultaneously, thereby reducing cycle times and maximizing throughput.

Cost Considerations

The cost of a professional pouch packing machine varies depending on factors such as capacity, features, and brand. Automatic pouch packaging machines from reputable manufacturers in Pune or other industrial hubs may range from several thousand to hundreds of thousands of dollars, depending on their specifications and capabilities.

On the other hand, tabletop pouch packing machines, which are smaller in size and capacity, are generally more affordable and can cost anywhere from a few hundred to several thousand dollars. While they may have lower production capacities compared to their industrial counterparts, tabletop machines are suitable for small-scale production or startup businesses with limited space and budget constraints.

In conclusion, automatic pouch packaging machines are indispensable assets in the food industry and various other sectors, offering unparalleled efficiency, precision, and reliability in packaging solutions. Whether it’s streamlining production processes, ensuring product quality and safety, or enhancing market competitiveness, these machines continue to revolutionize the way products are packaged and delivered to consumers worldwide. With advancements in technology and manufacturing capabilities, the future holds even greater promise for the role of packaging machines in shaping the landscape of modern industries.